| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Olang |

| Model Number : | OL-3000 |

| Certification : | ISO |

| Price : | Negotiable |

| Payment Terms : | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability : | 100 unit/month |

| Delivery Time : | 7 days |

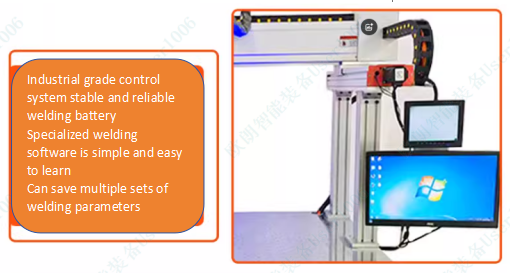

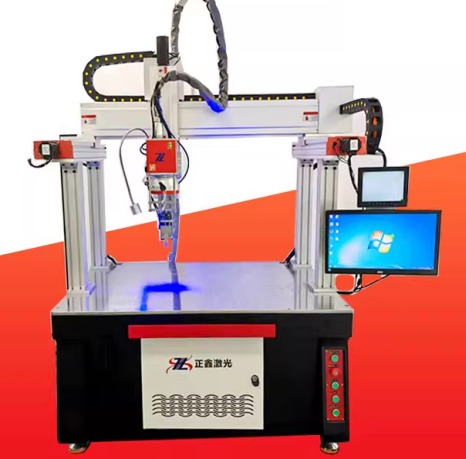

Equipment structure

Equipment advantages

High precision machining: Each axis has high positioning accuracy

and repeat positioning accuracy, such as X/Y/Z axis positioning

accuracy up to ± 0.05mm/m, repeat positioning accuracy ≤ 0.03mm/m;

The positioning accuracy of the C/A axis is ≤± 0.015 °, and the

repeatability accuracy is ≤ 0.005 °, which can meet the machining

requirements of high-precision parts such as aircraft engine blades

and automotive B-pillars.

High efficiency production: Through dual station design,

alternating clamping and welding can be achieved, greatly improving

work efficiency; At the same time, the quick changeover function

can complete the process switching of hot formed parts for

different vehicle models in a short period of time, supporting the

production needs of small batches and multiple varieties; In

addition, the high-speed cutting speed can reach 250mm/s, which is

3-5 times faster than traditional plasma cutting, effectively

shortening the processing time.

Complex shape processing: The design of multi axis linkage allows

the laser head to move freely in three-dimensional space, enabling

welding of various complex curved surfaces and shaped workpieces

without frequent replacement of fixtures, improving the flexibility

and adaptability of processing.

Intelligent control: Equipped with real-time focus control

function, high-speed energy sensor monitors laser power output,

maintaining a stability of 99%. The front-end independent profiling

axis follows the workpiece surface at high speed to optimize the

machining accuracy of corner parts; A vision system based on deep

learning can recognize defects such as porosity and undercutting,

and automatically adjust laser power or welding speed to achieve

quality traceability and automatic compensation, improving the

stability and reliability of welding quality

Application area

|